The oxygen sensor plays a pivotal role in ensuring the optimal performance of your vehicle’s engine. It provides crucial data to the engine’s computer, ensuring the right balance of air and fuel.

In this guide, we’ll delve deep into the intricacies of the 4-wire oxygen sensor, offering insights and step-by-step instructions to check its functionality. The 4-wire oxygen sensor is an advancement over the traditional one-wire system.

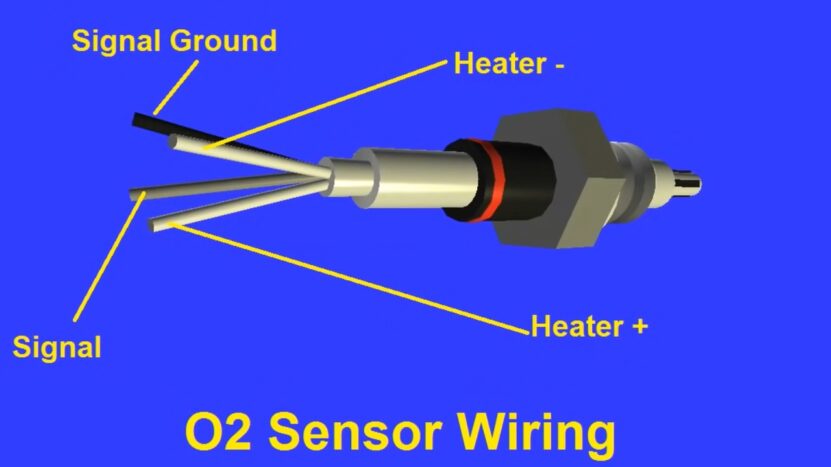

It’s designed to provide faster feedback to the engine’s computer, ensuring more precise fuel adjustments. Let’s break down its components.

The Four Wires Explained

- Heater Wires: Two of the wires are dedicated to heating the sensor. This built-in heater ensures the sensor starts functioning quickly, even before the engine warms up. Typically, on Ford vehicles, these are two white wires, while on GM and Chrysler, they might be black or have black stripes. However, the color can vary based on the make and model of the vehicle.

- Signal and Power Wires: The remaining two wires are for signal and power. These wires communicate the oxygen levels in the exhaust to the computer, allowing it to adjust the fuel mixture accordingly.

Preliminary Checks

Before diving into the actual testing, it’s essential to conduct some preliminary checks to ensure the sensor is in good condition.

Visual Inspection

Inspect the 4-wire harness wire’s routing and its grounding. Often, the sensor’s ground connection can become rusted, causing slow response times and potential fault codes.

Additionally, ensure the harness isn’t soaked in oil or anti-freeze. Contamination from these fluids can alter the sensor’s functionality.

If you notice any oil leaks, identify the source and address it. For wires soaked in fluids, clean them with brake clean spray, and dry them with air.

Ground and Power Supply Wires

Using a voltmeter, check the ground wires for voltage drop readings. A reading exceeding 0.250 volts indicates potential issues with the wire connections.

This test should be conducted with the engine both hot and cold, ensuring consistent readings. The heater wires require a 12-volt power supply.

This can typically be found on the second wire of Ford’s two white wires or GM’s two black stripe wires. Always measure this voltage using a voltmeter.

Actual Testing

Once the preliminary checks are complete, it’s time to delve into the actual testing of the 4-wire oxygen sensor.

Heater Wires

To confirm the heater wires are functioning correctly, poke them with a test light. If the light illuminates, they’re in good shape.

However, if the light doesn’t light up despite a 12-volt reading on the tester, it indicates a potential issue with the power supply wire.

Signal Wire Testing

The next step is to measure the signal wire leading to the computer terminal. Ideally, you should get a fluctuating reading between 0.1 volts to 0.9 volts when the engine is warmed up.

This reading shouldn’t be static; it should oscillate. To validate the reading, you can manually adjust the mixture by disconnecting a vacuum hose or introducing a carb cleaner spray to the throttle.

Changes in Oxygen Wiring on Newer Models

It’s essential to note that the standard 0.1 to 0.9-volt fluctuation doesn’t always apply, especially in newer models post the year 2000. In these vehicles, the readings can exceed 1.0 volts due to the redesigned oxygen sensor.

If you’re unsure about the correct fluctuations for your vehicle, it’s best to consult with a professional or refer to ATS.

Other Influencing Factors

Several other factors and sensors can influence the readings from your oxygen sensor:

- Related Sensors: TPS sensor, Coolant sensor, and Mass sensor can all impact the readings if they’re not functioning correctly.

- External Factors: Issues like a bad fuel regulator, defective fuel injector, intake manifold gasket leak, vacuum hose leak, or malfunctioning computer can all provide false oxygen sensor readings.

Tips and Tricks

- Fuel Additives: Be cautious when adding fuel additives. Some can damage the oxygen sensor’s sensing element.

- Ground Wire Testing: You can run a ground wire from the battery negative to the oxygen sensor circuit to test its integrity.

- Multiple Oxygen Sensors: If your engine has multiple sensors, ensure you’re testing the correct one. Always refer to a wiring diagram from ATS to avoid confusion.

Advanced Troubleshooting Techniques

Delving deeper into the world of oxygen sensors, there are a few advanced techniques that can be employed to ensure the optimal functioning of the 4-wire oxygen sensor.

Oscilloscope Testing

An oscilloscope can be a valuable tool when diagnosing issues with the oxygen sensor. By connecting it to the signal wire, you can observe the waveform produced by the sensor.

A healthy sensor will produce a consistent and regular waveform, oscillating between rich and lean readings.

Heater Circuit Resistance Check

To ensure the heater circuit is functioning correctly:

- Disconnect the oxygen sensor from the harness.

- Using a multimeter, measure the resistance across the heater circuit (typically the two white wires for Fords).

- Compare the reading to the manufacturer’s specifications. If the resistance is out of spec, the sensor’s heater circuit may be faulty and require replacement.

Sensor Response Time

A sluggish oxygen sensor can lead to poor fuel economy and increased emissions. To check the sensor’s response time:

- Connect a voltmeter to the sensor’s signal wire.

- Rev the engine and observe the voltage reading.

- A healthy sensor will quickly oscillate between low and high voltages as you rev the engine.

Common Misconceptions and Myths

With the plethora of information available, there are bound to be misconceptions surrounding the 4-wire oxygen sensor.

“All Oxygen Sensors Are The Same”

Different vehicles require different types of oxygen sensors, each tailored to the vehicle’s specific needs. Always ensure you’re using the correct sensor for your vehicle.

“Oxygen Sensors Need Regular Replacement”

While it’s true that oxygen sensors can wear out, they don’t have a set replacement interval. It’s best to monitor their performance and replace them when they start showing signs of malfunction.

The Importance of Quality Replacement Parts

When it comes time to replace your oxygen sensor, it’s crucial to invest in quality parts.

OEM vs. Aftermarket

While aftermarket sensors can be more affordable, they might not always meet the exact specifications of your vehicle. OEM (Original Equipment Manufacturer) parts are designed specifically for your vehicle, ensuring optimal performance and longevity.

FAQ

How do altitude or driving conditions affect the oxygen sensor’s readings?

Altitude can influence the amount of oxygen in the air. At higher altitudes, there’s less oxygen, which can affect the sensor’s readings. Similarly, extreme driving conditions, like towing heavy loads or aggressive driving, can cause the engine to work harder and may influence the sensor’s data. It’s essential for the vehicle’s computer to adjust the air-fuel mixture accordingly for optimal performance.

Can a car pass an emissions test with a faulty oxygen sensor?

It’s unlikely. A malfunctioning oxygen sensor can lead to increased emissions, which can cause a vehicle to fail an emissions test. If the check engine light is on due to a bad oxygen sensor, the car will most likely not pass the test.

Is there a difference between upstream and downstream oxygen sensors?

Yes. The upstream oxygen sensor (also known as the pre-catalytic converter sensor) monitors the oxygen levels in the exhaust gases before they pass through the catalytic converter. The downstream sensor (or post-catalytic converter sensor) checks the oxygen levels after the gases have been treated. Both sensors help manage engine performance and emissions, but they serve slightly different roles.

Can a faulty oxygen sensor impact the performance of the catalytic converter?

Yes. If the oxygen sensor is not providing accurate data, the air-fuel mixture may not be optimal. Over time, this can lead to an overworked catalytic converter, causing it to wear out or fail prematurely.

Do all modern vehicles use a 4-wire oxygen sensor?

No. While the 4-wire oxygen sensor is common, many modern vehicles, especially those manufactured after 2000, might use sensors with five or more wires. These sensors often have additional functionalities and can provide more precise readings to the vehicle’s computer. Always refer to your vehicle’s manual to determine the specific type of sensor used.

Final Words

The 4-wire oxygen sensor plays a pivotal role in your vehicle’s performance and emissions. Regular checks, coupled with a deep understanding of its functioning, can ensure your vehicle runs efficiently for years to come.

Remember, when in doubt, always consult with a professional or refer to your vehicle’s service manual. Safe driving!